British cycling heritage

Established in 1948 by Monty Young, Condor Cycles can be described as the very definition of British cycling heritage. We had a chat with Condor’s head of design, Ben Spurrier, about the current trends and why he believes Condor has been the key to the brand’s success (and what will keep them going for another 60 years).

Text: Silje Strømmen

Photos: Condor Cycles Archive

Photos Brooks bike: Mari Oshaug

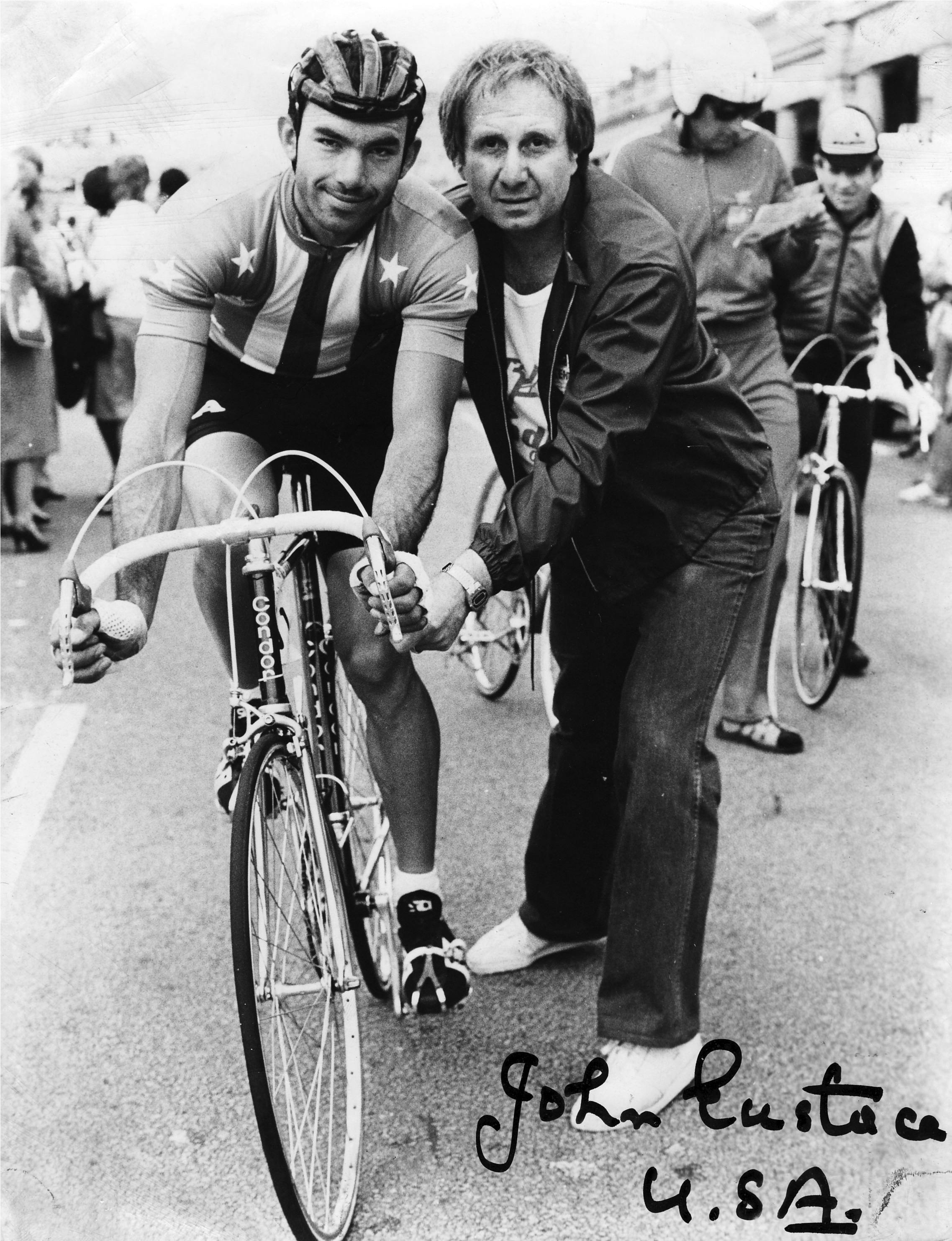

Few brands can claim to have their bikes ridden by cycling household names including Tom Simpson and Bradley Wiggins and to World Championships and the Tour de France. Today, Condor is a design driven brand with its family ethos and feel still intact.

The success Condor has experienced over the last sixty years has depended on being aware of current and future technologies. So many family-owned businesses have gone under due to the inability to re-invent themselves. The industry of cycling can be unforgiving and name and heritage alone is no guarantee. We had a chat with Condor’s head of design, Ben Spurrier, about the current trends and why he believes Condor has been the key to the brand’s success (and what will keep them going for another 60 years).

BV: What is the current “thing” in bike manufacturing?

BS: At Condor, steel has for a long time been a traditional material that we build with. It is also my personal favorite. People are still surprised by seeing this material at a high performance level. It is by many viewed as old-fashioned, heavy and outdated. At Condor however, we are doing something much more exciting and modern with it and these days we also have the technology to use it in that way. We are currently at the forefront in the resurgence of steel. The advancement in technology has allowed us to push the material so far that it can match the qualities of materials such as carbon fiber and aluminum. We still obviously use both materials in our bikes, but steel is what we have always been known for.

BV: And what would you say is the “next big thing” in bike manufacturing?

BS: I think that in the future 3D printing will have a massive impact on our ability to work with materials. 3D printing in metals is still highly specialised and very much out of our accessibility. But I think that in the future, as that technology starts to trickle down, it will become much more widespread and available.

BV: Why do you think Condor has managed to stay in its position for such a long time?

BS: I think it is a state of mind that we all adopt where we are passionate about staying at the front. We are very aware that you cannot just do what you have always done, or you will stagnate. Ultimately, in the grand scheme of things, we are a small-scale manufacturer. Therefore we need to work twice as hard to make sure that we are pushing forward, advancing and staying on trend. I think that perhaps that right there, that we always manage to stay on trend, is what keeps Condor going. We are flexible enough, small enough and open minded enough to try new and different things. We have always been open to trying new things, rather than getting stuck in our own way, unable to move forward, as a lot of smaller family owned business can be. It is very much a about the mindset. “This is how we have always done it, and why would we change that?” We are the opposite of that. We are constantly trying new things.

Interestingly the other thing that keeps Condor going, both as a brand and as a retailer, is that we are not pigeon holed to just selling high performance bicycles. There has long been a perception that Condor is high-end luxury bikes only. Our bread and butter is in fact selling touring and commuter bikes, far more everyday machines that people use to get to work on and that they use to go adventuring. It is actually the smaller end of our market that is our high performance stuff. Again, it is about that flexibility of being able to accommodate everyone and not just being pigeon holed into one corner of the market.